Five Reasons to Use Induction Heating for Shell Annealing

For ammunition manufacturers, consistency is critical. When it comes to shell annealing, the traditional methods of flame or furnace heating can be...

APPLICATIONS

APPLICATIONS: More

APPLICATIONS: More

APPLICATIONS: More

INDUSTRIES

INDUSTRIES: More

INDUSTRIES: More

INDUSTRIES: More

PRODUCTS

PRODUCTS: More

SERVICES: More

LEARN

LEARN: More

ABOUT

Ambrell, a leading source of innovative applications of induction heating, today launched its next generation EKOHEAT® products, featuring Versatile Performance Architecture (VPA) Technology. A first-of-its-kind in the industry, the EKOHEAT product line with VPA TechnologyTM makes induction processes easy, safe and serviceable.

Easy-to-Use

Safety

Serviceable

For additional information call +1 585 889 9000 or visit the Ambrell website at www.ambrell.com.

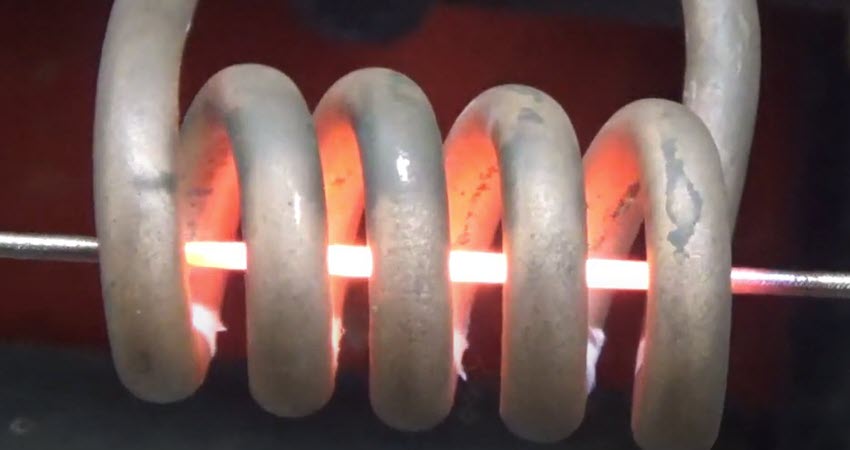

For ammunition manufacturers, consistency is critical. When it comes to shell annealing, the traditional methods of flame or furnace heating can be...

Induction heating is commonly used in the manufacture of a variety of tools including screwdrivers, garden tools, knives, drill bits and much more....

Annealing, a heat treatment process, softens metals by altering their internal structure, making them more workable. But traditional methods like...