Production Automobile

Dans l’industrie automobile, le chauffage par induction a été utilisé à des fins de production des pièces de grande taille pour la carrosserie, moteur, système électrique, système de direction, système de carburant et système d’échappement. Avec des systèmes de chauffage par induction qui couvrent une très vaste plage de fréquences, nous sommes capables de chauffer des pièces de toutes dimensions. Les pièces de plus grande taille, telles que, des engrenages d’arbres à cames sont chauffées à des fréquences inférieures alors que des pièces plus petites comme, par exemple, des circuits électriques flexibles sont chauffe à des fréquences supérieures.

Notes d’Application relatifs à la Production Automobile

Cliquez ici pour savoir comment le chauffage par induction permet d’augmenter l’efficience, l’efficacité et la sécurité de vos procédés de la production automobile.

Chauffage par induction

Il est une méthode rapide, efficace, précise et répétable, sans contact permettant de chauffer les métaux ou les autres matériaux conducteurs d'électricité. Le matériau peut être un métal comme de l'acier, du cuivre, de l'aluminium, du laiton ou cela peut être un semi-conducteur comme du carbone, du graphite ou du carbure de silicium. Pour chauffer les matériaux non conducteurs comme le plastique ou le verre, l'induction est utilisée pour chauffer un suscepteur conducteur d'électricité, habituellement le graphite, qui transfère ensuite la chaleur du matériau non conducteur.

Lisez notre brochure de quatre pages "À propos du chauffage par induction"

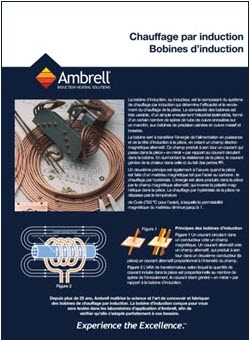

Bobines d'Induction

La bobine d’induction, ou inducteur, est le composant du système de chauffage par induction qui détermine l’efficacité et le rendement du chauffage de la pièce.

La bobine sert à transférer l’énergie de l’alimentation en puissance et de la tête d’induction à la pièce, en créant un champ électromagnétique alternatif.

Brasage, brasage tendre, moulage, durcissement, recuit, scellement-verre-métal, collage et encore d’autres procédés qui peuvent bénéficier grâce aux systèmes de chauffage par induction modernes.

L’induction vous offre:

- Chauffage sélectif

- Maximum de reproductibilité

- Cycles beaucoup plus courts

- Grande précision

- Installation flexible

- Réduction des émissions

- Rentabilité accrue

- Nouvelle interface

- Rebuts et réusinage réduits