Note: Annealing lip on cryogenic dewar

Objective:

Annealing a lip on aluminum cryogenic dewar that has been work hardened during the process of spin forming.

End Product:

Aluminum dewar

Equipment:

Ambrell 3.5 kW induction heating system, equipped with a remote workhead containing one 1.0μF capacitor.

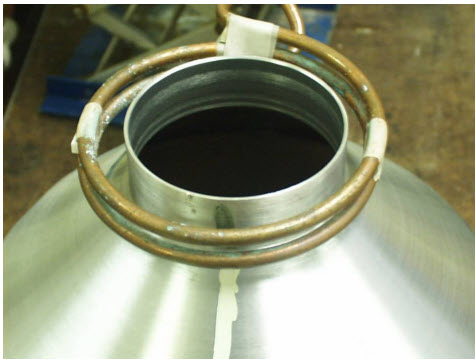

An induction heating coil designed and developed specifically for this application.

Materials:

Aluminum dewar, lip has a 3.24 in (82.3mm) ID and is 0.05 in (1.3mm) thick

Temperature:

800 °F (427 °C)

Frequency:

303 kHz

Testing:

A two turn helical coil is used to heat the lip on the cryogenic dewar. The dewar is placed in the coil and power is applied for 2 minutes to anneal the required 1 in heat zone.

Benefits:

Induction heating provides:

-

Hands-free heating that involves no operator skill for manufacturing

-

Fast, controllable, accurate heating

-

High efficiency, low energy cost

-

Even distribution of heating

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000