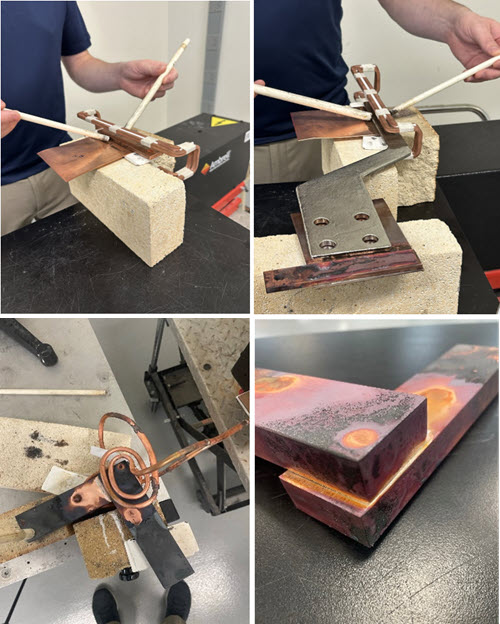

Note: Brazing Copper Buss Plates without Torches

Objective:

To braze copper buss plates without torches

End Product:

copper buss plate

Equipment:

Ambrell EKOHEAT 45 kW induction heating system, equipped with a remote heat station containing eight 1.0 μf capacitors for a total capacitance of 8.0 uf

Materials:

Customer-supplied copper buss plates

Temperature:

1400 °F(~700 °C)

Frequency:

54 - 65 kHz

Testing:

Initial tests were conducted to optimize the power delivered to the part and to understand the heating patterns achieved. After several changes and iterations on the coil setup the following data is collected from the testing. Heat times of 3-5 minutes were observed for the parts.

Braze alloy was preplaced into the joint as the copper bars heated to temperature. A foot pedal operation would allow operator to have flexibility in pulsing the power into the joint as needed.

Benefits:

-

Speed: The client was able to braze the assembly faster than they would have with their flame heating process.

-

Safety & Efficiency: There is no open flame with induction heating, and it also introduces less heat into the work environment. It is also more efficient than most other heating

-

methods such as torch heating.

-

Repeatability: The client can expect the same result in the same amount of time every single time with induction heating. Torch heating, on the other hand, is highly dependent on operator skill and consistency.

-

Lab Expertise: THE LAB at Ambrell designed a solution that met the client"s goals.

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000