Note: Conveyor steel plate heating

Objective:

Heat steel plates on conveyor system in order to cook Welsh cakes.

End Product:

Welsh cakes

Equipment:

Ambrell 40 kW induction heating system, equipped with a remote workhead containing one 1.3 μF capacitor.

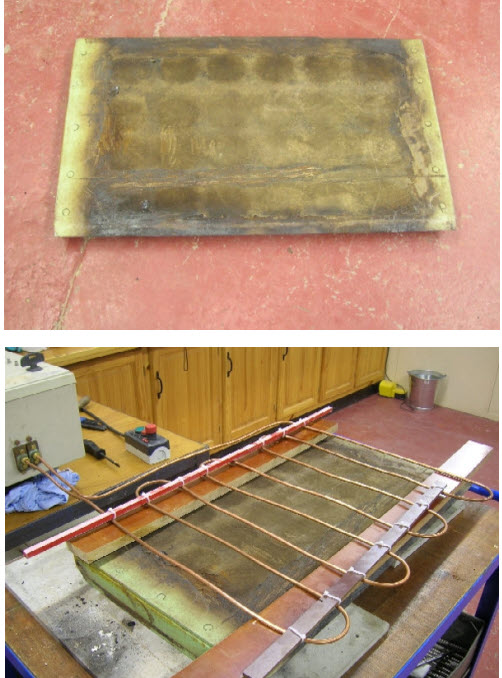

An induction heating coil designed and developed specifically for this application.

Materials:

Steel plate 760 x 440 x 10mm (29.9 x 17.3 x 0.4 in.)

Temperature:

200 °C (392 °F)

Frequency:

87 kHz

Testing:

A flat serpentine heating coil under the steel conveyor system heats the steel plate to a uniform temperature of 200 °C (392 °F) in approximately 3 minutes. The Welsh cakes are placed on the hot steel plate and cook for 1ĂË minutes. The conveyor moves the cakes off the coil where they are flipped. A second pass over the coil cooks the other side.

Benefits:

-

Clean heat directed only to the steel plates. Minimal heat is radiated to the adjoining areas.

-

Safe, comfortable working conditions for the operators

-

Lower operating cost compared to gas-fired ovens.

-

Reduced cost to run air conditioning system because less heat is released into the working environment.

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000