Note: Drying Steel Rings with Induction Heating

Objective:

To heat streel rings for a drying application; the client was using hot air but it wasn't completely drying the rings

End Product:

Streel ring

Equipment:

Ambrell EKOHEAT 20 kW, 15-40 kHz induction heating system with a workhead and coil specifically designed for this application

Materials:

Magnetic steel rings

Temperature:

121 °C (250 °F)

Frequency:

22 kHz

Testing:

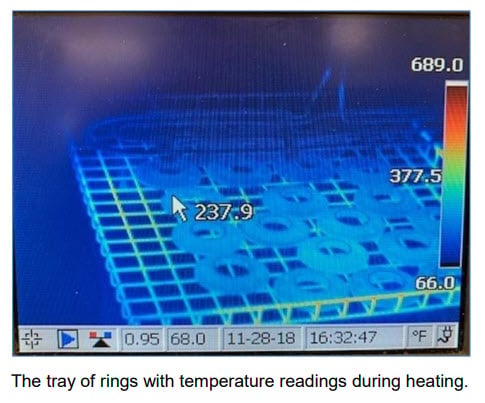

A custom-designed single position multiple-turn pancake coil was built to generate the required heating for the application. A thermal imaging camera was used to measure the temperature of the parts during the heating trials. 24 parts were loaded onto the client-provided magnetic steel grated tray. The tray was mounted on a linear motion, motorized sled programmed to run at a rate that would heat one tray per minute.

To prevent overheating the side rails, the parts were grouped near the center of the tray to allow for a coil design that did not need to extend to the sides of the tray. The parts were sprayed with water before the heating cycle. All parts were observed to be completely dry at the end of the heating cycle.

Benefits:

- Speed: Induction rapidly and completely dried the tray of rings.

- Repeatability: The client can expect the same result in the same amount of time every single time.

- Effectiveness: Induction completely dried the rings, whereas hot air was not as effective

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000