Note: Forging a steel bar form a u-bolt

Objective:

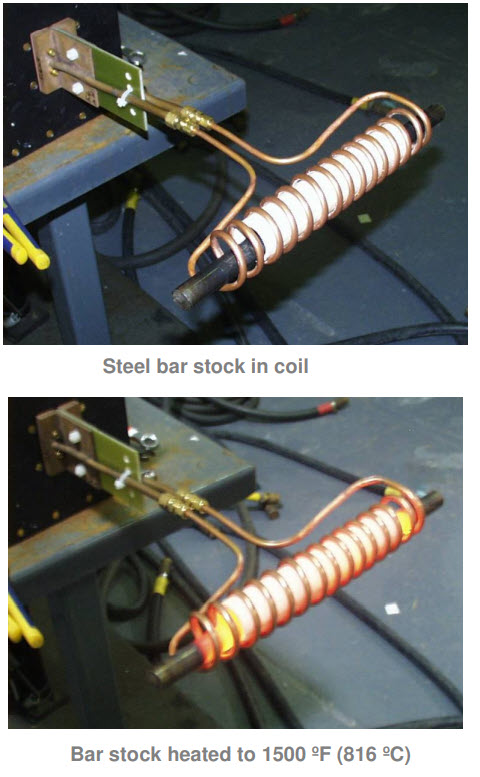

Preheating round steel bar stock prior to forging a hot formed u-bolt

End Product:

Steel U-bolt

Equipment:

Ambrell 135 kW induction heating system, equipped with a remote workhead containing eight 1.0 μF capacitors for a total of 2.0 μF

An induction heating coil designed and developed specifically for this application

Materials:

.795 in (20.19 mm) diameter round steel bar stock 15 in (381 mm) long

Temperature:

1500 °F (816 °C)

Frequency:

88 kHz

Testing:

A fifteen turn helical coil with ceramic insert is used to preheat the 15 in (381 mm) section of steel bar stock. Power is supplied for 9.90 seconds to heat the whole piece to 1500 °F (816 °C). The piece is then placed in a die and formed into a u-bolt.

Benefits:

-

Uniform through heating

-

High volume, rapid forging

-

Scale formation reduced, steel does not remain above oxidation temperature for long periods of time

-

Fast, energy-efficient heat

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000