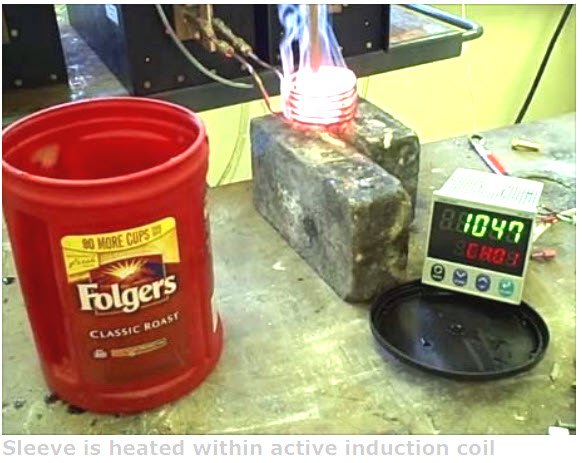

Note: Hardening steel pipe segments (sleeves)

Objective:

Induction is used in a process to harden a steel pipe segment to improve wear-resistance

End Product:

Steel pipe

Equipment:

Ambrell 15 kW, 100 kHz induction heating system, equipped with a remote workhead containing four 2.0 μF capacitors for a total of 2 μF

An induction heating coil designed and developed specifically for this application to cover the range of wire

diameters.

Materials:

Steel pipe segments: 1.6 in (40 mm) outer diameter, 0.125 in (3 mm) wall 2 in (50 mm) tall

Temperature:

1832 °F (1000 °C)

Frequency:

88 kHz

Testing:

A five-turn helical coil is used to heat the steel sleeve. The distance between the coil turns is adjusted to provide uniform heat to the steel part. The parts are quenched in a 7% polymer quench following the heat cycle to achieve a hardness of RC40.

Benefits:

- heat directly into the part, saving energy and time precise control of heating

- even distribution of heating along the part

- faster production rates & increased production

- a flameless process

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000