Note: Heat a Fixture for a Wire Heating Application

Objective:

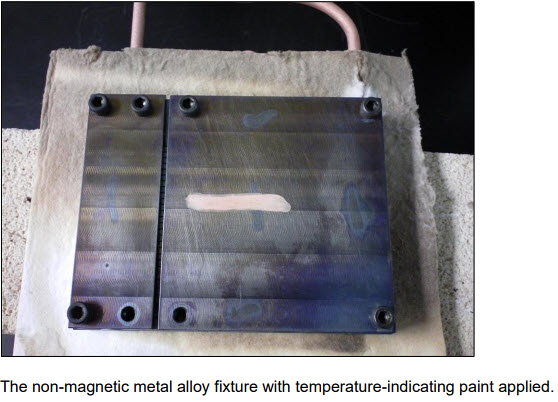

Heat a non-magnetic metal alloy shape-setting fixture for a Nitinol wire heating/shaping application.

End Product:

Nitinol wire

Equipment:

Ambrell EASYHEATTM 6 kW 150-400 kHz induction heating system with a workhead and coil specifically designed for this application

Materials:

Non-magnetic alloy fixture

Temperature:

977 °F (525 °C)

Frequency:

249 kHz

Testing:

THE LAB determined that a specially-designed single position multiple-turn channel coil would be optimal for this application. Temperature indicating paint was applied to the part so it would clearly indicate when the fixture achieved 977 °F (525 °C). It took seven minutes for the EASYHEAT to heat the fixture to temperature. An oven had been heating this fixture to temperature in twelve minutes.

Benefits:

-

Speed: The client had been using an oven, and induction shaved five minutes off of the heating time

-

Footprint: An EASYHEAT and its workhead require a minimal footprint, whereas an oven requires a significant footprint

-

Energy Efficiency: Induction heating is more efficient than an oven; with induction only the fixture is heated

-

Lower Maintenance Costs: Ovens can have significant maintenance costs and downtime with requirements such as relining

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000