Note: Heat an Inconel tube for swaging

Objective:

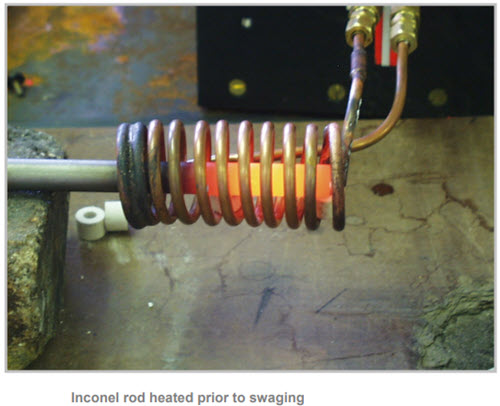

An Inconel tube is pre-heated prior to a swaging operation

End Product:

Inconel tube

Equipment:

Ambrell 15c 15kW induction heating system, equipped with a remote workhead containing three 1.0ĂĹşF capacitors for a total of 3 μF

An induction heating coil designed and developed specifically for this application.

Materials:

3 in Inconel blanks

~.5 in dia; optical pyrometer

Temperature:

1800 °F (815 °C)

Frequency:

105 kHz

Testing:

A 12-turn helical coil is used for the required heat pattern. With the application of 11kW of RF energy, the tube is heated to the required temperature 10 seconds. (For a 5-second cycle time, or for a larger part diameter, a 30 kW power supply is recommended.)

A need to increase volume and quality of parts production led to the choice of an induction process over flame. Handling is minimized and continuity is assured with the precision delivery of heating only where required.

Benefits:

-

Hands-free heating that involves no operator skill for manufacturing

-

Even distribution of heating

-

Localized application of energy

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000