Note: Heat Setting A Shape Memory Alloy

Objective:

Heat a steel die to 975 °F (523.8 °C) to set (cure) a shape memory alloy in the correct position.

End Product:

Shape memory alloy

Equipment:

Ambrell 3kW induction heating system equipped with a remote workhead containing one 1.0 ÂľF capacitor

An induction heating coil designed and developed specifically for this application.

Materials:

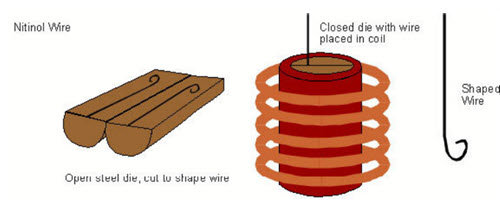

Nitinol wire

2 in (50.8 mm) diameter tapered steel die

steel tube to house the die

instant adhesive

Temperature:

975 °F(523.8 ÂşC)

Frequency:

131 kHz

Testing:

A five-turn helical coil is used to heat the steel die. The Nitinol wire is set into the die and tacked into place using instant adhesive. The die is placed inside a larger steel tube. The die cure is heated to 945 ÂşF (507.2 ÂşC) in 75 seconds. Successful heat setting of the Nitinol wire is achieved in 15 seconds

Benefits:

-

Fast, accurate, repeatable heating

-

Heat precisely delivered only to where it is needed

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000