Note: Heat steel pliers handle for bending

Objective:

Heat pliers for final shaping of the handles

End Product:

Pliers

Equipment:

Ambrell 2 kW induction heating system, equipped with a remote heat station containing two 0.33 μF capacitors for a total of 0.66 μF.

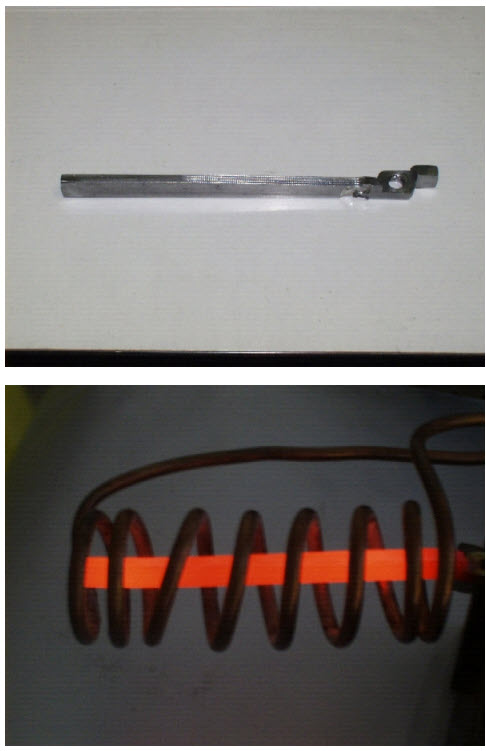

An induction heating coil designed and developed specifically for this application.

Materials:

Steel pliers handles 5 in (12.7 cm) long; 0.14 in (3.56 mm) thick

Temperature:

1200 °F (649 °C)

Frequency:

199 kHz

Testing:

A multi-turn helical coil is used to heat a 3.75 in (9.53 cm) long zone on one handle of the pliers at a time. The coil design allows easy loading and unloading without having to rotate the part. The handle is inserted into the coil and heated for 30 seconds to reach 1200 °F. Then the part is transferred to a press and formed into the correct handle shape. Multiple pliers handles may be heated simultaneously with a higher kW power supply.

Benefits:

Precisely heating the desired zone avoids overheating of part. This provides higher quality vs. heating with a torch.

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000