Note: Heat varying steel plates on the same line

Objective:

To heat steel plates of various thicknesses on the same line

End Product:

Steel plates

Equipment:

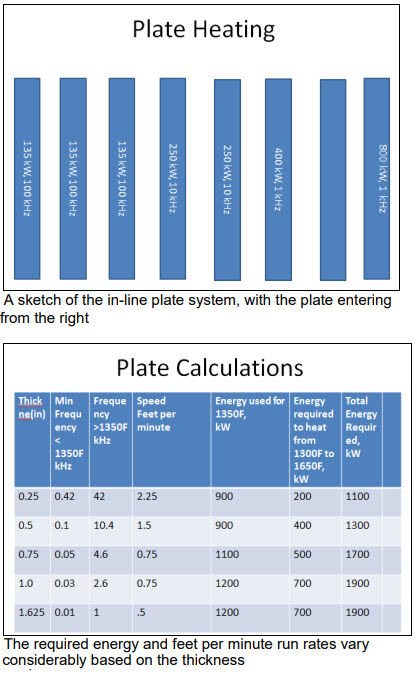

Ambrell (1) EKOHEAT 800kW/1 kHz, (1) 400kW/1 kHz, (2) 250kW/10 kHz and (3) 135kW/100 kHz power supplies

A series of coils in-line for each induction heating system

Materials:

Steel plates that are 8 feet (2.4m) wide by 20 feet (6m) long with thicknesses ranging from 0.25âÂÂ-1.65â (6.4- 41.9mm)

Temperature:

1650 °F (899 °C)

Frequency:

1-100 kHz

Testing:

A line consisting of 7 Ambrell induction heating systems will be set up, with the part entering the coil of the EKOHEAT 800kW/1 kHz and moving along in-line to progressively less powerful/higher frequency systems. This arrangement is due to the variation in thickness among the plates which must run in the same line. Thin plates will run at a more rapid speed, while thick plates will run at a slower speed.

With heating occurring above curie, the result is a considerable change in load at that point. Additionally, the depth of heating grows significantly above curie. This results in lower frequency systems not being able to heat thinner plates effectively. For that reason, higher frequency power supplies were needed in this line too.

Benefits:

-

Versatility: This in-line system enables the client to heat plates with significantly different thicknesses

-

Speed: While the feet per minute varies considerably based on the thickness of the part, induction is a fast method of heating steel plates to temperature

-

Precision: Induction offers the precision and control necessary to heat plates of varying thicknesses in the same line to the same temperature

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000