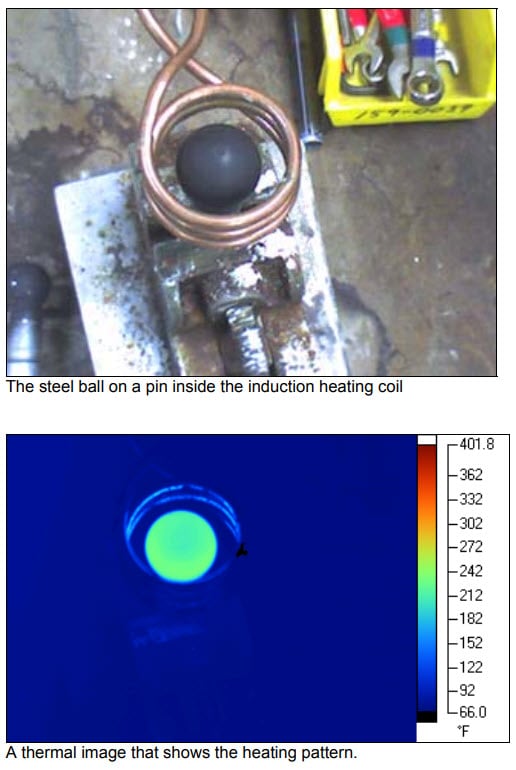

Note: Heating a steel ball on a pin by induction for an insertion application

Objective:

To heat a steel ball on a pin to 212 °F (100 °C) for insertion into a nylon joint cup assembly to create automatic suspension ball studs

End Product:

Steel ball

Equipment:

Ambrell EASYHEAT 3542 LI, 4kW 150-400 kHz induction heating system equipped with a remote heat station containing two 1.5 μF capacitors

A single-position three-turn induction heating coil designed and developed specifically for this application

Materials:

Customer-supplied 1.4 in (35 mm) steel ball attached to a pin

Temperature:

212 °F (100 °C)

Frequency:

217 kHz

Testing:

The part was painted with black paint in order to make the emissivity of the body as close to one as possible. The part was then placed into the coil and the power was turned on. After two seconds, the power was turned off. Five seconds later a thermal image was captured that demonstrated the heat pattern at the point of insertion. With a 4 kW Ambrell EASYHEAT power supply, the part can be heated to temperature in two seconds or less.

Benefits:

-

Speed: While the project is new, the customer wanted the part to be heated to temperature within four seconds, and that was easily achieved and exceeded with the EASYHEAT power supply

-

Precision: The customer only wanted the ball area to be heated, which was achieved thanks to inductionâÂÂs precise heating

-

Part quality: Induction has provided a superior quality part that met the client's objectives

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000