Note: Heating a steel grenade for a disposing application

Objective:

To heat a steel grenade to 800 °F (427 °C) for a disposing application

End Product:

Grenade

Equipment:

Ambrell EASYHEAT 10 kW, 150-400 kHz induction heating power supply with a remote workhead containing two 1.00 μF capacitors for a total of 0.5 μF.

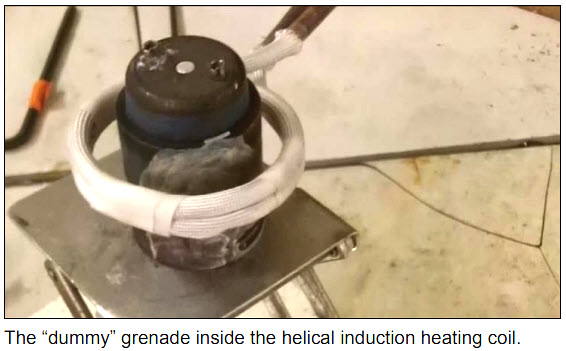

A single-position two-turn helical induction heating coil designed and developed for this application

Materials:

Steel indummy in grenade

Temperature:

800 °F (427 °C)

Frequency:

245 kHz

Testing:

Temperature indicating paint was applied to the outside of the grenade casing. The grenade was then placed inside the coil and power was turned on. After two seconds the painted indicated that the part achieved 800 °F (427 °C).

Benefits:

-

Direct, precise heating: Only heats the portion(s) that need(s) to be heated

-

Repeatability: Induction is highly repeatable and easy to integrate into manufacturing processes

-

Fast heating: Significantly faster than other techniques such as torch and oven heating

-

Clean and flameless: Which makes it safer and more repeatable

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000