Note: Heating a steel mold for rubber seal vulcanization

Objective:

To heat a steel mold evenly to 392 °F (200 °C) to be used on a press for rubber seal vulcanization

End Product:

Rubber seal

Equipment:

Ambrell 30 kW induction heating system, equipped with a remote workhead containing eight 0.3 μF capacitors for a total of 0.6 μF

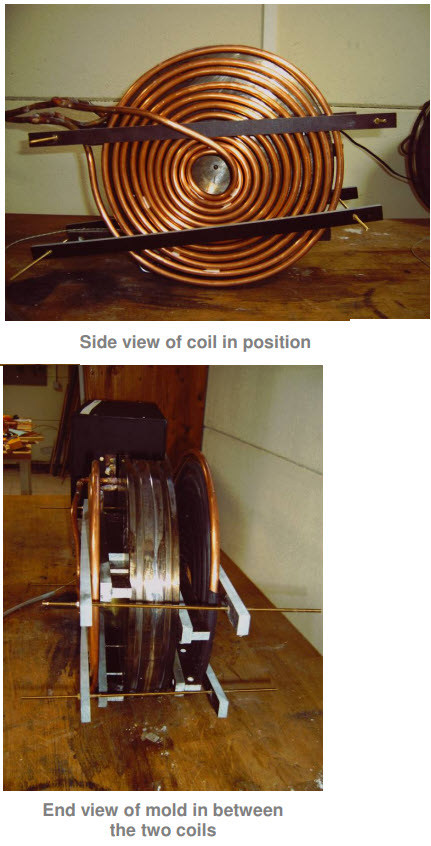

An induction heating coil designed and developed specifically for this application

Materials:

Steel mold 13.4 in (340 mm) diameter, 2.16 in (55 mm) width, approximately 77.2 lbs (35 kg)

Temperature:

392 °F (200 °C)

Frequency:

78 kHz

Testing:

Two thirteen-turn pancake coils are used to heat both sides of the mold simultaneously for 170 seconds to reach an external temperature of 392 °F (200 °C). The power is continually decreased over the next 390 seconds to reach a uniform temperature of 392 °F (200 °C) ĂÄ 41 °F (5 °C) throughout the mold.

Benefits:

- Repeatable and consistent heat

- Quicker process time, increased production

- Even distribution of heating

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000