Note: Heating a steel part before application of rubber molding

Objective:

To preheat two irregularly shaped steel castings to be molded and bonded with synthetic rubber

End Product:

Steel casting

Equipment:

Ambrell 30 kW induction heating system, equipped with a remote workhead containing four 1.0 μF capacitors (for a total of 1.0 μF)

An induction heating coil designed and developed specifically for this application

Materials:

Two steel castings, 17 lb. irregularly shaped, approximately 6 x 9 x 1 in (152 x 229 x 25.4 mm)

Temperature:

400 °F (204 °C)

Frequency:

92 kHz

Testing:

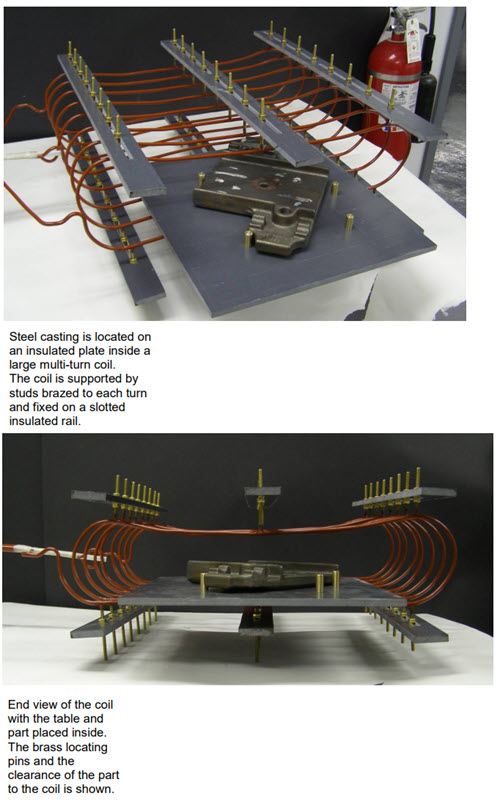

Two steel castings are placed onto an insulated plate with brass guide location pins. The plate is placed onto a table which slides into a large multi-turn helical coil. The parts are induction heated to 400 °F in 180 seconds. The slow heating time allows the parts to come up to temperature evenly. When the heating cycle is completed each part is placed into a press for the molding and bonding operation.

Benefits:

-

efficient and repeatable heat vs. a torch or an oven

-

even heating of parts throughout

-

easy loading and unloading of the parts

-

flexibility for varying bulk castings sizes and geometries

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000