Note: Heating a steel tie down (loosen steel pin)

Objective:

Heat steel tie downs on containers to loosen steel pin so pin can rotate

End Product:

Steel tie-down assembly

Equipment:

Ambrell 10 kW induction heating system, equipped with a remote workhead containing two 1.5 μF capacitors for a total of 0.75 μF

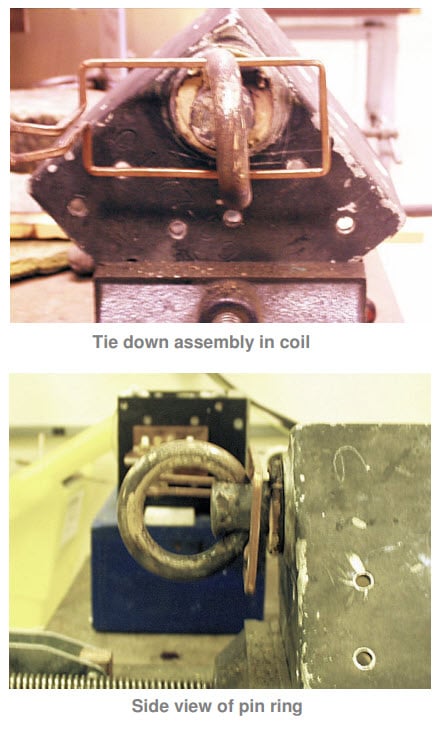

An induction heating coil designed and developed specifically for this application

Materials:

Steel tie-down assembly with a 2.5 in (63.5 mm) dia. flange

1 in (25.4 mm) dia. rod and pin ring approx 4 in (101.6 mm) OD

0.75 in (19.05 mm) thick steel

Temperature:

1000 °F (538 °C)

Frequency:

282 kHz

Testing:

A single-turn helical coil is used to heat the assembly. The coil is placed around the pin and power is applied for 120 seconds. After heating, a steel rod is inserted in the pin ring, pressure is applied and the pin ring spins freely.

Benefits:

-

Precise and accurate placement of heat without affecting surrounding areas

-

Much faster process time, from hours to minutes

-

Repeatable and consistent results

-

Even distribution of heating

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000