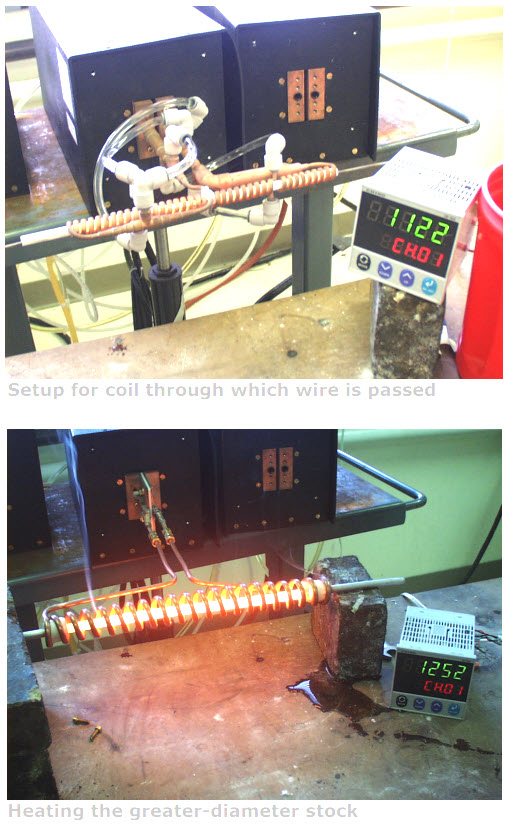

Note: Heating a steel wire for tempering

Objective:

Induction is applicable to a continuous tempering process in which wire stock is fed through an induction coil at production speeds.

End Product:

Steel wire

Equipment:

Ambrell 65 kW, 100 kHz induction heating system, equipped with a remote workhead containing eight 1.0 μF capacitors for a total of 2 μF

Three induction heating coils designed and developed specifically for this application to cover the range of wire diameters.

Materials:

Steel wire 3 mm to 12 mm diameter

Temperature:

1922 °F (1050 °C)

Frequency:

90 kHz

Testing:

Wire stock is fed through a forty-turn helical coil at a rate of 6 meters/minute, reaching the desired temperature to effect the tempering process. A similar 20 turn helical coil is used for the largest wire diameter

Process required maintenance of 6 stock feed-lines into a gas-fired furnace with disappointing heat transfer into wires of smaller diameters. Induction requires 50% less energy and reduces production-line footprint by 90%

Benefits:

-

heat directly into the wire, saving energy and time

-

easy integration into production line, improving throughput

-

precise control of heat

-

even distribution of heat within the wire

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000