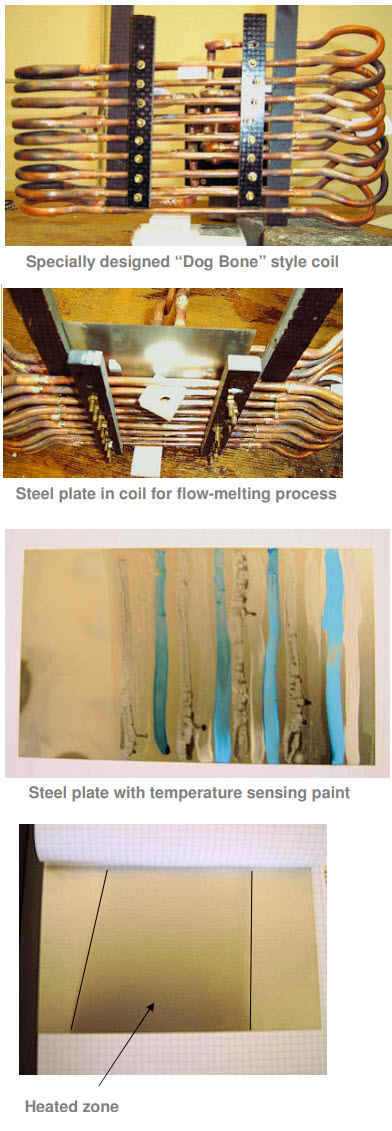

Note: Heating a tin-coated steel plate (flow-melting)

Objective:

Heat a carbon steel plate coated with tin to 450 °F (232 °C) for flow-melting

End Product:

Steel plate

Equipment:

Ambrell 4.2 kW induction heating system, equipped with a remote workhead containing two 0.5 μF capacitors for a total of 0.25 μF

An induction heating coil designed and developed specifically for this application.

Materials:

7.9 x 4.7 in (200 x 120 mm) steel plates with a tin layer of 100 to 1000 nm thickness

temperature sensing paint

water for quenching

Temperature:

450 °F (232 °C)

Frequency:

354 kHz

Testing:

A nine-turn dog-bone style coil is used for the flow-melting* process. The tin coated carbon steel plate is placed in the coil for 1.34 seconds to uniformly reflow the tin coating. The plate is then quenched in cool water to retain sufficient free tin at the surface.

*Flow-melting: a process by which the 'as deposited' tin is heated above its melting point of 232 °C and is quickly quenched in cool water resulting in a composite coating iron/tin alloy and iron/tin which exhibits a bright reflective appearance

Benefits:

-

Uniform heating

-

Rapid focused heat

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000