Note: Heating aluminum wire to create screens

Objective:

To heat aluminum wire for a wire coating curing application

End Product:

Wire coating

Equipment:

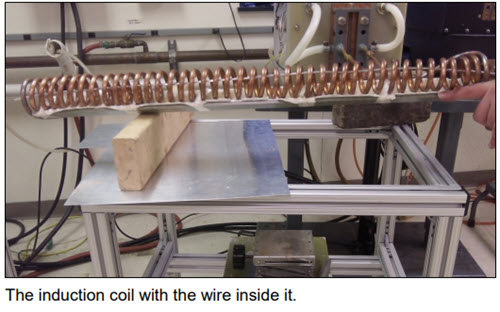

Ambrell EKOHEAT 50 kW, 15-45 kHz induction heating power supply with a remote workhead A single position, forty turn helical coil (2.5 in /0.8 m long) designed and developed for this application

Materials:

Aluminum wire (0.145 in /3.7 mm)

Temperature:

450 °F (232 °C)

Frequency:

18 kHz

Testing:

Temperature indicating paint was used to indicate when the wire met temperature. It took just 3 seconds for the wire to achieve 450 °F (232 °C). In production, there will be a coating which may require slightly more energy. Since it was not included during testing a precise number cannot be given, but heating time should be in that

vicinity

Benefits:

-

Speed: Induction will double production due to more rapid heating than infrared lamps can offer; with induction 100 feet per minute can be run instead of 50 feet per minute with infrared

-

Repeatability: Induction is highly repeatable and easy-to integrate into manufacturing processes

-

Working Environment: Induction introduces less heat into the work environment than competitive processes

-

Applications Lab: This client was working with a competitor but decided to work with Ambrell due to Ambrell in s superior responsiveness and expertise

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000