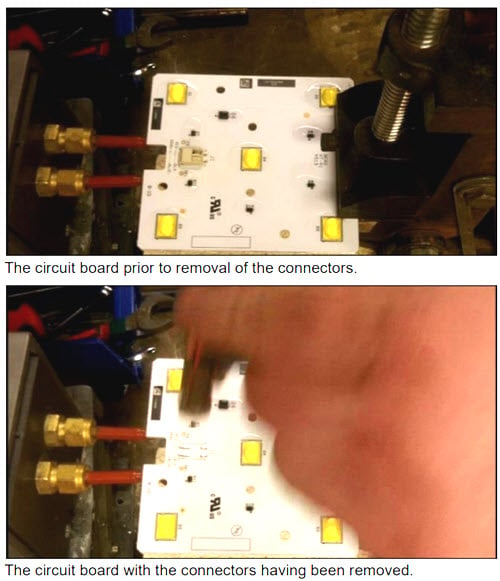

Note: Heating an aluminum-backed circuit board - solder reflow

Objective:

To heat an aluminum-backed circuit board to temperature to reflow solder and remove bad connectors from LEDs. This application is in the medical device manufacturing segment.

End Product:

Circuit board

Equipment:

Ambrell EASYHEAT 2 kW, 150-400 kHz induction heating power supply with a remote workhead containing two 0.66 μF capacitors

A single position, three-turn pancake induction heating coil designed and developed for this application

Materials:

Aluminum backed circuit board

Temperature:

600 °F (316 °C)

Frequency:

287 kHz

Testing:

The circuit board was placed over the pancake coil and the power was turned on. After some initial testing, it was determined that 20 seconds of heating time enabled the connectors to be easily removed.

Benefits:

-

Speed: The client was using a hot plate, which required over one minute of heating. So induction proved to be significantly faster

-

Throughput: Given the significantly faster heating time, induction improved the throughput for this client

-

Energy savings: Induction is a more efficient heating method than hot plate heating, saving the client money

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000