Note: Heating an Aluminum Tube for Bending

Objective:

Heat an aluminum tube for a bending application in the automobile accessory industry

End Product:

Aluminum tubing

Equipment:

Ambrell EASYHEAT 3.5 kW 150-400 kHz induction heating system with a workhead and coil specifically designed for this application

Materials:

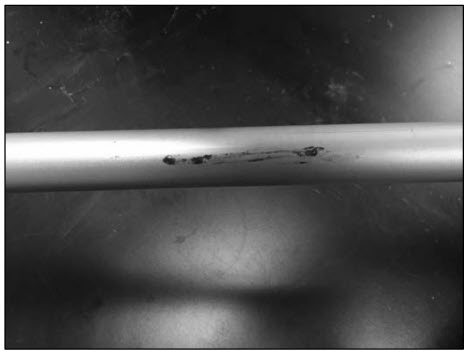

Aluminum tube (1 in/25.4 mm diameter, 0.125 in/3.2 mm wall)

Temperature:

500 °F (260 °C)

Frequency:

260 kHz

Testing:

THE LAB determined that a specially-designed single position multiple-turn split-helical coil would be optimal for this application. Temperature indicating paint was applied to the part, which dissolves when the part reaches the targeted temperature. It took 120 seconds for the 3.5 kW EASYHEAT to heat the aluminum tube to temperature. A higher power system would offer faster results, but this was sufficient for the process. A torch was used for this application, but induction presented speed and quality advantages.

Benefits:

-

Speed: The client had been using a torch, and induction reduced the required heating time

-

Energy Efficiency: Induction heating is more efficient than a torch

-

Repeatability: Unlike a torch, induction delivers the same result time after time

-

Safety: Induction does not present an open flame into the work environment like a torch, resulting in a safer working environment

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000