Note: Heating an Inconel tube (incineration)

Objective:

Heating a 4 in diameter tube that is 12 in long to 1800 °F (982 °C) in a progressive manner with four heating sections in order to incinerate materials and create energy

End Product:

Inconel tube

Equipment:

4 Ambrell EKOHEAT, 800kW 0.5-1.5 kHz induction heating systems

Materials:

Inconel tube

Temperature:

1800 °F (982 °C)

Frequency:

0.7-1.5 kHz

Testing:

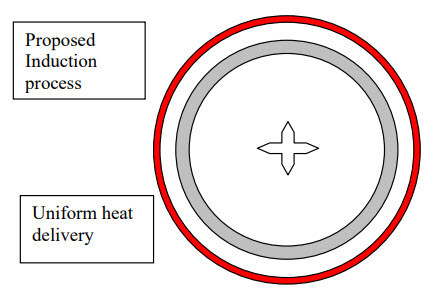

With there being four heating zones, four EKOHEAT 800kW/1 kHz induction heating systems would be leveraged. Each heating zone would be 3â long and have a 6 in dead band in between each zone. Materials would enter one side of the tube, they would be heated up, and ultimately incinerated for the purpose of creating and capturing energy. Ceramic fiber insulation between the tube and coil reduces heat loss to the environment. A constant air gap between the tube and coil provide uniform heat delivery to the tube.

Benefits:

-

Uniform heating: Induction offers uniform heating, which flame does not offer

-

Efficiency: Induction is more efficient than the alternative, which leverages a flame

-

Speed: Induction can rapidly melt the materials

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000