Note: Heating Copper Wire for Stripping

Objective:

To heat pre-tinned copper wires of various diameters to 500 °F (260 °C) to melt the tin and to coalesces (fuse) the wires for easier stripping

End Product:

Copper wire

Equipment:

Ambrell 2.5 kW, 13.56 MHz solid state induction power supply equipped with a remote heat station containing three 100 pF capacitors for a total of 300 pF.

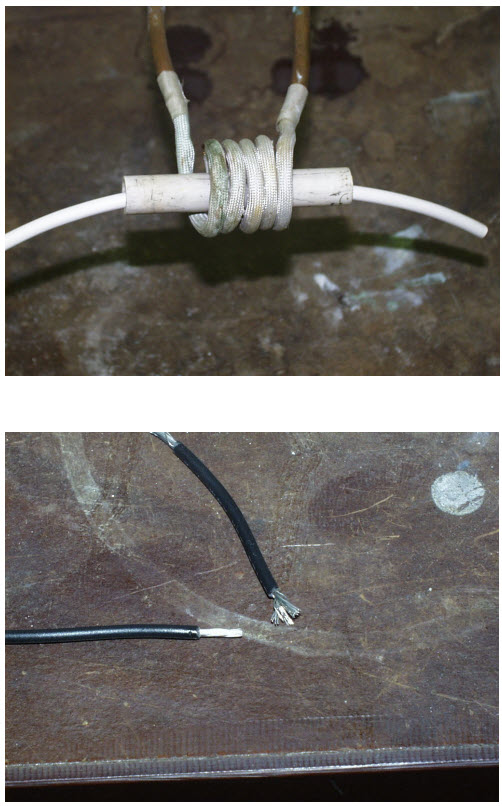

An induction-heating coil designed and developed specifically for this application

Materials:

Pre-tinned copper wires 0.01 mm in diameter

Temperature:

500 °F (260 °C)

Frequency:

13.56 MHz

Testing:

A multi-turn induction heating coil is used for heating the various wire samples. A ceramic tube is placed inside the coil to act as a guide for the wire and to center the wire, preventing arcing in the coil. Initial tests are performed to ensure that the individual copper strands are heating to the right temperature. It is determined

that the strands can be heated to melt and coalesce the copper in 1-2 seconds at this frequency

Benefits:

The Ambrell 2.5 kW system heats the various diameter wires to 500 Ă °F at the rate specified. The same system works on a single multi-stranded wire as well as a dual multi-strand wire assembly. Up to 20 kW of power at 400 kHz could not heat the small copper wires.

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000