Note: Heating Graphite Discs

Objective:

To heat an assortment of graphite discs of variable sizes; the client was from the aerospace industry.

End Product:

Graphite discs

Equipment:

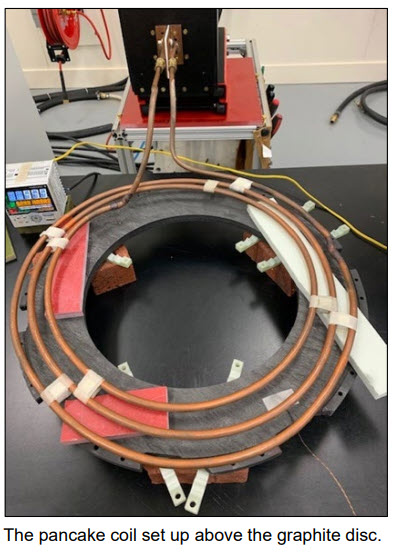

Ambrell EKOHEAT 45 kW, 50-150 kHz induction heating power supply with a workhead and coil specifically designed for this application.

Materials:

Graphite discs

Temperature:

200 °F (93 °C)

Frequency:

N/A

Testing:

A custom-designed single position multiple-turn pancake coil was built to generate the required heating for this application. Initial tests were conducted to optimize the power delivered to the part. The coil was held 0.5 in (12.7 mm) above the top surface of the part. Thermocouples were attached to the top and bottom surfaces of the part. It took 45 seconds to heat the sample to the target temperature of 200 °F (93 °C) on the surface closest to the coil. The surface farther from the coil reached 180 °F (82 °C) in this time. It is possible to use closed-loop temperature control with the EKOHEAT to bring the top surface to temperature and hold it while the farther surface is brought to temperature.

Benefits:

-

Speed: Induction met the client's heating time objective.

-

Repeatability: The client can expect the same result in the same amount of time every single time.

-

Efficiency: Induction can efficiently heat the part in a controlled manner to only deliver the required heat.

-

Footprint: Induction, with a movable workhead, is often considerably more space efficient than alternative heating methods.

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000