Note: Heating iron oxide nanoparticle solution

Objective:

Heating 14 ml samples of iron oxide in an aqueous solution for nanoparticle research

End Product:

Nanoparticle solution

Equipment:

Ambrell 2.4 kW induction heating system, equipped with a remote workhead containing two 0.1 μF capacitors for a total of 0.2 μF

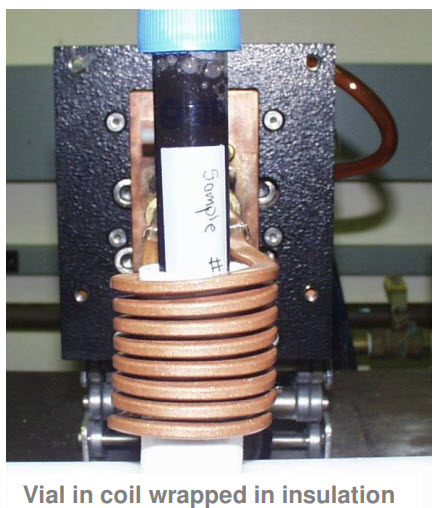

An induction heating coil designed and developed specifically for this application.

Materials:

Solution 1 - 14ml sample iron oxide (Fe3O4) nanoparticles diluted 800x

Solution 2 - 14ml sample iron oxide (Fe3O4) nanoparticles diluted 100x

Optical temperature probe

Temperature:

80.6 - 91.4 °F (27-33 °C)

Frequency:

336 kHz

Testing:

An eight-turn helical coil is used to heat the vials. 0.0625 in thick insulation is wrapped around the vial and the vial is placed in the coil. The optical temperature probe is inserted into the vial with the base of the probe located in the middle of the coil turns. Only the portion of the solution located in the coil range heats.

Benefits:

-

Rapid and localized heating

-

Uniform controllable heat

-

Small bench top footprint

-

Even distribution of heat

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000