Note: Heating stainless-steel inserts

Objective:

To heat stainless steel inserts for the automotive industry

End Product:

Stainless steel inserts

Equipment:

Ambrell EASYHEAT 2 kW, 150-400 kHz induction heating power supply with a remote workhead containing two 0.17 μF capacitors for a total of 0.34 μF.

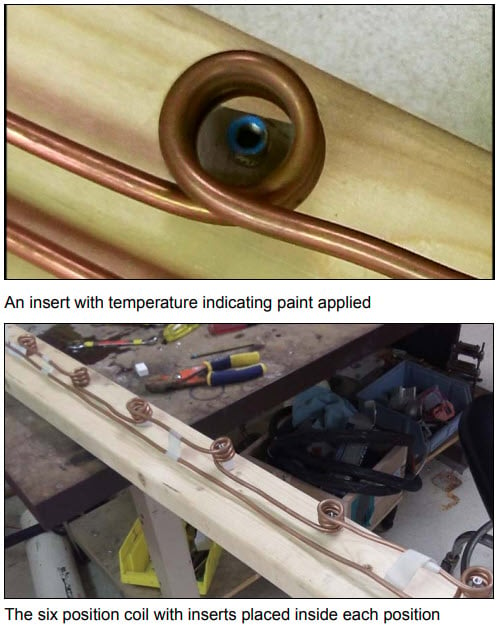

A six position three-turn helical induction heating coil designed and developed for this application

Materials:

Stainless steel metal inserts (3/8 in/9.5 mm long, an OD of .25 in/6.4 mm and an ID 0.1875 in /4.8 mm)

Temperature:

500 °F (260 °C)

Frequency:

230 kHz

Testing:

The inserts, with temperature indicating paint applied, were placed inside the six position helical induction heating coil and the power was turned on. The parts heated to 500 °F (260 °C) within ten seconds. The client had been using ultrasonic heating to press in the inserts which took 90 seconds.

Benefits:

-

Speed: Induction offers dramatically faster heating when compared to ultrasonics

-

Increased production: Faster heating means there is the potential to dramatically increase production rates

-

Repeatability: Induction is highly repeatable and easy-to integrate into manufacturing processes

-

Energy efficiency: Induction offers fast, flameless, instant on/instant off heating

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000