Note: Heating Steel Assemblies for Sealing

Objective:

To heat steel assemblies for a sealing application; the client manufactures plastic filtration devices and was looking to replace their resistive heating method.

End Product:

Steel assemblies

Equipment:

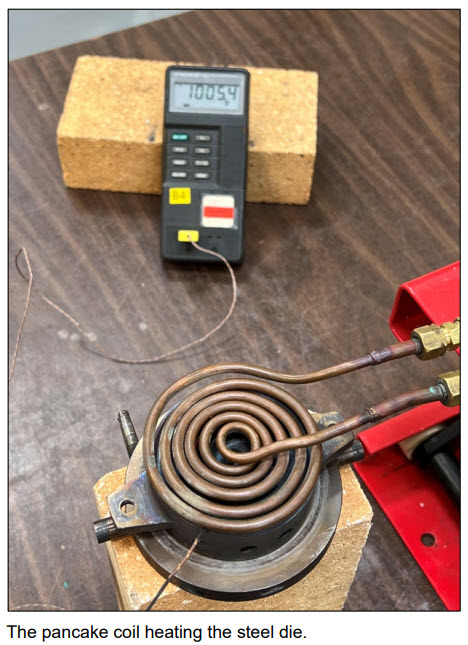

Ambrell EASYHEAT 2.4 kW, 150-400 kHz induction heating power supply with a workhead and coil specifically designed for this application.

Materials:

Steel assemblies

Temperature:

1000 °F (538 °C)

Frequency:

180 kHz

Testing:

A single position multiple-turn pancake shaped coil was built to generate the required heating for the application. Initial tests were conducted to optimize the power delivered to the part. Temperature indicating paints were used to determine the heating time. It took seven minutes to heat the sample to temperature, easily exceeding the objective as the client's goal was to achieve temperature in under fifteen minutes.

Benefits:

-

Speed: Induction heating easily surpassed the client's heating time goals.

-

Repeatability: The client can expect the same result in the same amount of time every single time.

-

Size of System/Workhead: Induction is more space efficient than an oven.

-

Efficiency: Thanks to there being no ramp up time and instantaneous heating, induction is a more efficient method of heating.

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000