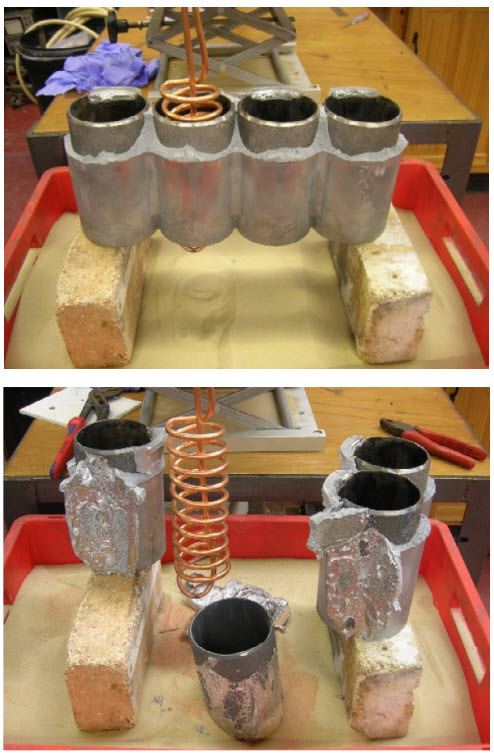

Note: Heating steel liners (engine head)

Objective:

Heat steel liners on the head of an engine to remove aluminum casing.

End Product:

Engine head

Equipment:

Ambrell 10 kW induction heating system, equipped with a remote workhead containing one 2.6μF capacitor.

An induction heating coil designed and developed specifically for this application.

Materials:

Steel, 80 mm ID x 190 mm (3.1 in x 7.5 in.)

Temperature:

650 °C (1202 °F)

Frequency:

81 kHz

Testing:

An internal 10 turn solenoid (bore) coil is used to heat the steel liner to 650 °C (1202 °F) in approximately two minutes. Pressure is applied to the outer aluminium skin to loosen it from the steel. A four position coil can be used to heat 4 liners simultaneously.

Benefits:

Precise direct heat to disengage the aluminium quickly and cleanly. The aluminium casing is recycled and reused thereby reducing scrap and cutting costs.

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000