Note: Heating Steel Pipe for a Casting System

Objective:

To heat steel pipe; the client is looking to replace their resistive heating process that takes 15 minutes to reach temperature.

End Product:

Steel pipe

Equipment:

Ambrell EKOHEAT 15 kW, 50-150 kHz induction heating power supply with a workhead and coil specifically designed for this application.

Materials:

Magnetic and non-magnetic steel

Temperature:

850 °F (454 °C)

Frequency:

N/A

Testing:

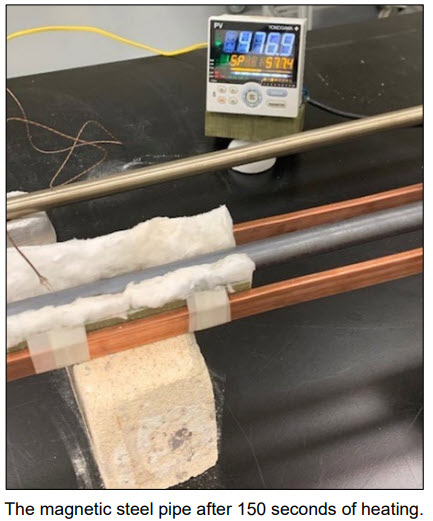

A custom-designed single position channel coil was built to generate the required heating for the application. Temperature indicating paint was then applied to the part, which dissolves when the part reaches temperature. For both the magnetic and nonmagnetic steel pipes, it was observed that it took 150 seconds to heat the sample to temperature. A thermocouple was welded to each part and heated from room temperature to verify the paint test results. Each was heated to temperature in less than 3 minutes.

Benefits:

-

Speed: Induction dramatically reduced the heating time they experienced with resistive heating as it dropped from 15 minutes to 3 minutes.

-

Repeatability: The client can expect the same result in the same amount of time every single time.

-

Efficiency: Induction heats just the portion of the part that requires heating.

-

Footprint: Induction, with a movable workhead, is often considerably more space efficient than alternative heating methods

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000