Note: Heating Steel Shafts for Forming (Medical Tools)

Objective:

To heat steel shafts for forming to manufacture medical tools; the client wasn't using a heating process previously.

End Product:

Medical tools

Equipment:

Ambrell EASYHEAT 6 kW, 150-400 kHz induction heating power supply with a workhead and coil specifically designed for this application.

Materials:

Stainless steel (magnetic and non magnetic) and nickel alloy

Temperature:

800 °F (427 °C)

Frequency:

N/A

Testing:

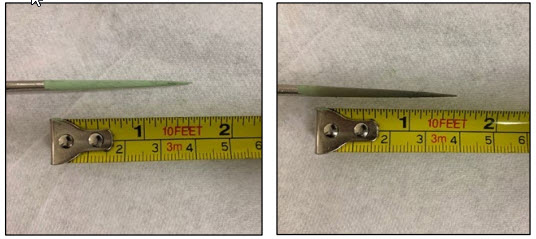

A custom-designed single position multiple-turn helical coil was built to generate the required heating for this application. Initial tests were conducted to optimize the power delivered to each part. Temperature indicating paint was then applied to each part, which dissolves when the part reaches 800 °F (427 °C). It was observed that each sample could be heated to temperature in 2 seconds. Since non-magnetic materials do not couple to induction as well as magnetic materials, considerably more power is needed to heat the non-magnetic stainless-steel part to the target temperature in the same amount of time as the magnetic nickel alloy and stainless steels. The magnetic stainless and nickel alloy steel parts could be heated to the target temperature in 1.0 second.

Benefits:

-

Speed: Induction met the client's heating time objective.

-

Repeatability: The client can expect the same result in the same amount of time every single time.

-

Efficiency: Induction can efficiently heat the part in a controlled manner to only deliver the required heat.

-

Footprint: Induction, with a movable workhead, is often more space efficient than other heating methods.

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000