Note: Heating Wires and Strips for Coating Removal

Objective:

Removal of the coating on various wires and strips

End Product:

Coating removal

Equipment:

Ambrell EASYHEAT 4 kW 150-400 kHz induction heating system with a workhead and coil specifically designed for this application

Materials:

Various polymer-coated aluminum strips and enamel-coated copper strips and wires

Temperature:

N/A

Frequency:

380 kHz

Testing:

A specially-designed single position multi-turn helical coil was built to generate the required heating for the application. Initial tests were conducted to optimize the power delivered to the parts.

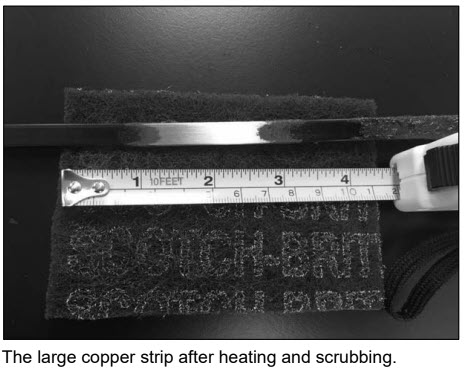

It was observed that all parts coated with enamel heated as expected by the customer. The coating darkened to black when heated. It was then easily scrubbed off. The copper wires required between 5 and 10 seconds to heat the enamel coating sufficiently.

The polymer coating on the aluminum strips behaved differently when heated. Visually, the coating turned brown and bubbly when the aluminum strip was heated. To avoid overheating and melting the aluminum, the best way to remove the polymer coating was to heat it only to the point of being soft enough to scrape off with a utility knife. This heating can be achieved in 10 to 15 seconds.

Benefits:

-

Speed: Both material types heated quickly to enable coating removal

-

Repeatability: Induction delivers the same result time after time, bringing consistency into their process

-

Safety: Induction does not present an open flame into the work environment like methods such as torch heating, resulting in a safer working environment

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000