Note: Oxidation of Graphite Anodes

Objective:

Heating carbon graphite anodes to destructively oxidize the parts to process embedded contaminants

End Product:

Carbon graphite anodes

Equipment:

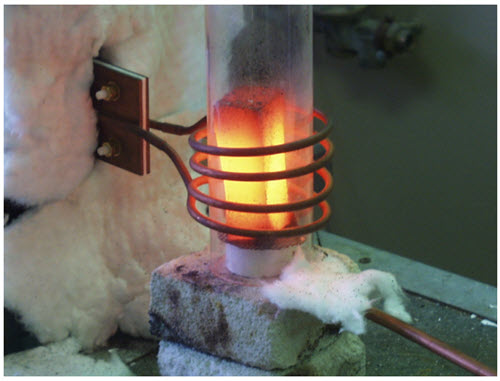

Ambrell 20 kW induction heating system, custom multi-turn helical coil, 4 cap 1.0 μF workhead

Materials:

anodes 2.5 x 2.5 x 4 in (63 x 63 x 102 mm)

Temperature:

1900 °F (1000 °C)

Frequency:

154 kHz

Testing:

An air purge system is used to provide fresh air (â 25 f3/hr) to the part during the heat cycle and to provide a swirling action for maximum contact with the surface of the anode. The anode is placed inside the induction-heating coil and heated to a temperature of 1000 °C. After 2.5 hours, the anode burns to about 0.375 in diameter piece. A pyrometer/controller is used to provide constant temperature as the anode reduces in size.

Benefits:

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000