Note: Oxidizing a chromel grid

Objective:

To heat a chromel grid for an oxidation application; the end product is a power generator

End Product:

Power generator

Equipment:

Ambrell EASYHEAT 9 kW, 150-400 kHz induction heating power supply with a remote workhead containing two 1.0 μF capacitors

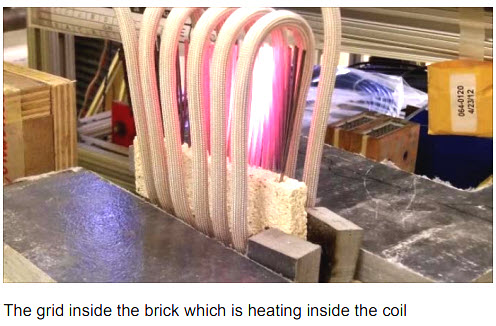

A single position, five-turn helical induction heating coildesigned and developed for this application

Materials:

Chromel grid

Temperature:

1700 °F (927 °C)

Frequency:

200 kHz

Testing:

The grid was placed into a brick and the brick was positioned into the coil. The power was turned on and the part began to heat. The part heated to temperature within 30 seconds. Uniform heating can be a challenge with this part, but it can be achieved with the correct approach. The part must stand straight, the coil should be made of thick tubing to prevent pulling action, and finally, moving the grid back and forth inside the coil can help facilitate the oxidation process.

Benefits:

-

Speed: The client was using a furnace, which took approximately three minutes, so induction dramatically reduced the heating time

-

Throughput: The dramatic reduction in heating time enabled a significant increase in production

-

Energy savings: Induction is a more efficient heating method than furnace heating

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000