Note: Preheat steel for reforming

Objective:

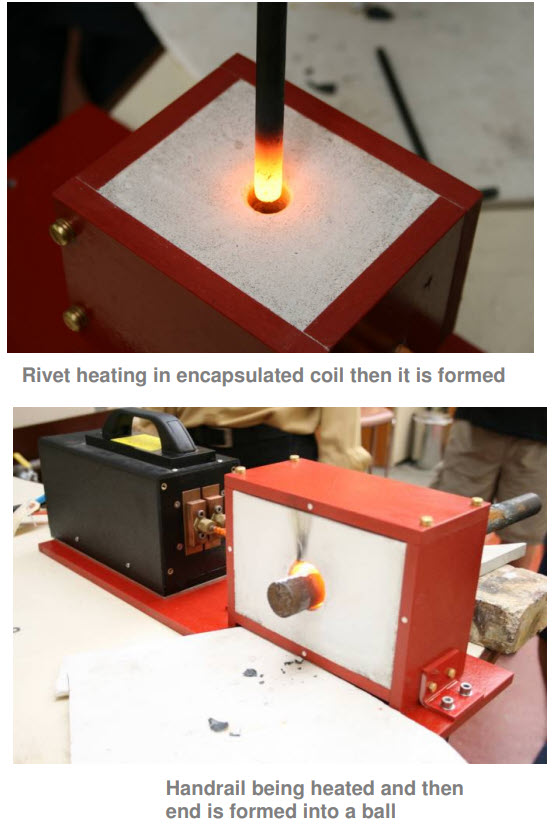

Preheat low carbon steel rivets and handrail bars for reforming for construction

End Product:

Handrail bars

Equipment:

Ambrell 10 kW induction heating system, equipped with a remote workhead containing two 1.5 μF capacitors for a total of 0.75 μF

An induction heating coil designed and developed specifically for this application

Materials:

Low carbon steel rivets 7/16â (11.1mm) dia x 1.5â (38mm) & 1.9â (47mm) long, low carbon bar 1.25â (32mm) dia x 3â (75mm) heat zone

Temperature:

1922 °F (1050 °C)

Frequency:

248 kHz for the rivets 155 kHz for the bars

Testing:

A three-turn encapsulated helical coil is used for the rivets and a four-turn encapsulated helical coil is used for preheating the handrail bars. The rivets are heated to the 1922 °F (1050 °C) in 22-25 seconds and the bars are heated to the 1922 °F (1050 °C) in 4 mins 43 seconds.

Benefits:

-

Controllable heat pattern

-

Ease of on site location use

-

Safe, no open flames

-

Even distribution of heating

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000