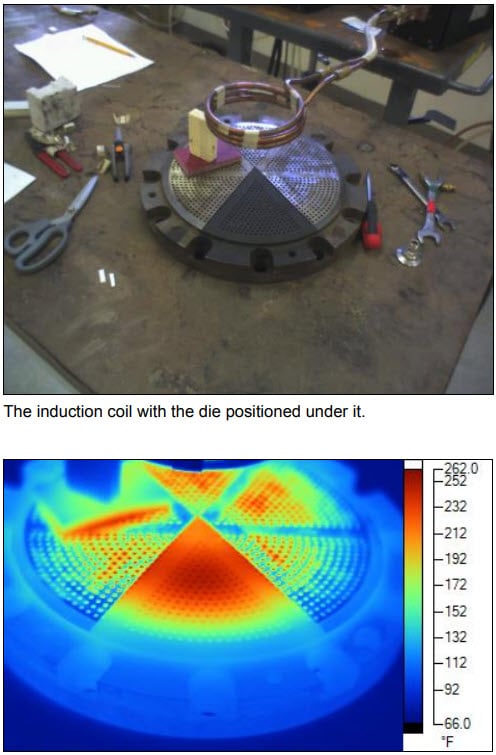

Note: Preheating a magnetic steel die

Objective:

To preheat a magnetic steel die; the end product is tubing and fittings

End Product:

Tubing and fittings

Equipment:

Ambrell EKOHEAT 15 kW, 50-150 kHz induction heating power supply with a remote workhead. A single position, three turn helical coil designed and developed for this application

Materials:

Steel die

Temperature:

250 °F (121 °C)

Frequency:

115 kHz

Testing:

The die was placed under the induction coil, approximately 3.5 in (89 mm) away from it to simulate production conditions. With an EKOHEAT 15 kW power supply under simulated production conditions, the die can heat to temperature within ten minutes. A key benefit over the client in s resistance heater is there will no longer be a need to open the chamber to remove the heater.

Benefits:

-

Speed: The client in s resistance heater took more than ten minutes to heat the die to temperature

-

Footprint: Induction requires a minimal footprint, saving valuable floor space

-

Setup: An induction coil (ceramic) can remain in the client in s chamber and expedite the process.

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000