Note: Preheating a titanium billet prior to rolling

Objective:

To preheat a titanium billet to 1800 °F prior to entering a rolling mill

End Product:

Titanium billet

Equipment:

Ambrell EKOHEAT 200kW 1.5-4.5 kHz induction heating system equipped with a remote work head containing six 40 μF capacitors

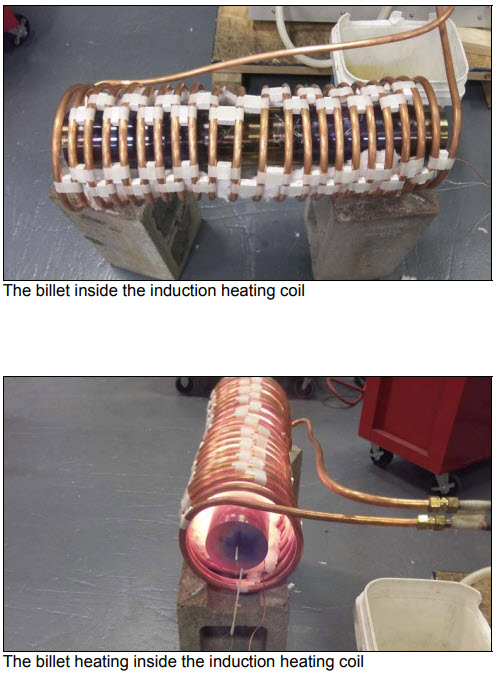

A multi-turn helical induction heating coil designed and developed specifically for this application

Materials:

Customer-supplied 4 in (102 mm) diameter, 24 in (610 mm) long titanium billet

Temperature:

1800 °F (1000 °C)

Frequency:

2.7 kHz

Testing:

The titanium billet was placed inside the multi-turn induction heating coil. The part was heated for five minutes, which was necessary to reduce the temperature difference between the center and outside of the billet. Due to the considerable diameter of the part, a high power, low frequency induction power supply was used.

Considerable effort went into designing the coil to ensure the most uniform heating possible while still minimizing heating time.

Benefits:

-

Speed: Induction heated the large billet quickly, and will also heat the client's longer 15 foot billets

-

Uniform heating: InductionâÂÂs rapid, even heating enabled a uniform temperature throughout the billet

-

Repeatability: This process will provide consistent results, so the client can design their process around the five-minute heating time

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000