Note: Preheating steel garden tools for press stamping

Objective:

Preheating various size blades and knives for garden tools

End Product:

Steel garden tools

Equipment:

Ambrell 15 kW induction heating system, equipped with a remote workhead containing six 1.0 μF capacitors for a total of 6.0 μF

An induction heating coil, designed and developed specifically for this application

Materials:

Steel pieces of various size 0.16 in (4 mm) thick

Temperature:

1562 °F (850 °C)

Frequency:

57-80 kHz

Testing:

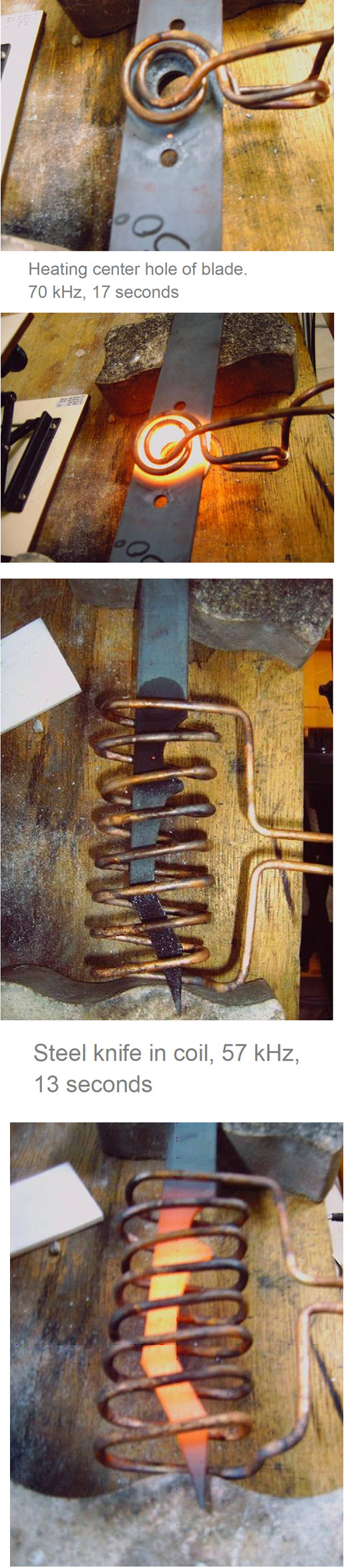

Three different coils are used for this heating application

âÂË A two turn pancake coil for the blade

âÂË A eight turn rectangular helical coil for the knives

Pieces are placed in their specific coil for heating. For the blades, the center hole must be heated to 1562 °F (850 °C) and for the knife 2/3 of the blade must be heated. Depending on the piece, the steel reaches 1562 °F (850 °C) in 13-19 seconds. After the metal is preheated it is press stamped.

Benefits:

-

Hands-free heating that involves no operator skill for manufacturing

-

Configurable heating profiles

-

Faster process times

-

Even distribution of heating

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000