Note: Preheating Steel Tubes Prior to Bonding

Objective:

To heat steels tubes for a bonding application; the end product is a bushing for large trucks. Induction would replace an oven for this

client.

End Product:

bushing for large trucks

Equipment:

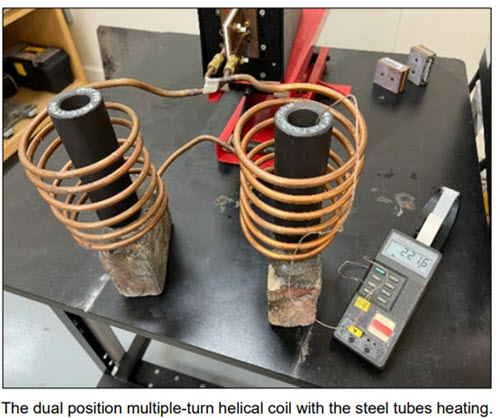

Ambrell EASYHEAT 8.3 kW, 150-400 kHz induction heating power supply with a workhead and coil specifically designed for this application.

Materials:

Cold-rolled steel tubes

Temperature:

220 °F (104.4 °C)

Frequency:

180 kHz

Testing:

A custom-designed dual position multiple-turn helical coil was built to generate the required heating for the preheating application. Initial tests were conducted to optimize the power delivered to the part. Thermocouples were used to measure temperature. Noise in the thermocouples disappears when power is turned off for a few seconds during the heat cycle. Heating took 90 seconds, which was the client's target.

Benefits:

- Repeatability: Induction delivers the same result every single time, making it ideal for a high-volume application.

- Speed: Induction has no warm-up time like an oven, and heating was relatively quick, resulting in a faster heating time for the client.

- Efficiency: Induction is highly efficient with no ramp-up time.

- Footprint: Induction takes up a modest amount of floor space, especially when you consider that the workhead can be placed a distance away from the power supply.

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000