Note: Sealing a Kovar tube

Objective:

To heat a Kovar tube for a glass sealing application; the end product is a vacuum tube

End Product:

Kovar tube

Equipment:

Ambrell EASYHEAT 4 kW, 150-400 kHz induction heating power supply with a remote workhead containing two 1.5 μF capacitors

A single position, two-turn helical induction heating coil designed and developed for this application

Materials:

Glass tubes

Kovar tubes

Temperature:

1800 °F (982 °C)

Frequency:

216 kHz

Testing:

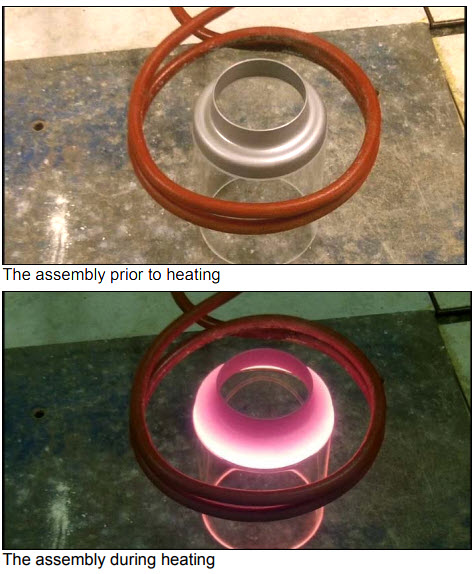

The Kovar tube was placed on the glass tube and the power was turned on. The Kovar tube began to heat and a constant output was maintained for 75 seconds. This enabled the Kovar to conduct its heat to the glass. At this point the Kovar began sinking into the glass and the power was turned down. A three minute ramp-down

process ensued to ensure that the glass would not crack. A heating profile was set on the EASYHEAT for this process.

In order to increase throughput, the client can instead acquire a 10 kW EASYHEAT, a four-position coil, and heat four parts every four minutes.

Benefits:

-

Speed: The client was using a torch, and operator error was slowing heating

-

Throughput: The repeatability of induction enables improved throughput

-

Energy savings: Induction is a more efficient heating method than torch heating

-

Quality: Consistency and repeatability equates to better quality and less scrap

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000