Note: Sintering Powdered Metals for Satellite Positioning System

Objective:

Heat tantalum tubing to sinter tungsten and tantalum material to tubing.

End Product:

Tantalum tubing

Equipment:

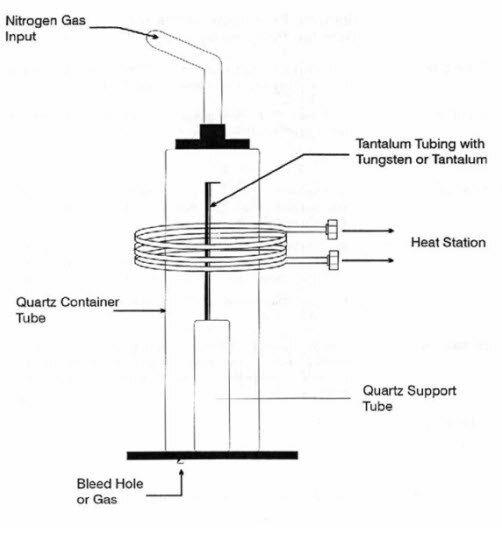

Ambrell 3.5kW induction heating system equipped with a remote workhead containing one capacitor equaling 1.25 μF

An induction heating coil designed and developed specifically for this application.

Materials:

Tantalum tubing 0.13 in (330.2 mm) diameter with tungsten and tantalum powdered material

quartz support tube

quartz container

nitrogen gas.

Temperature:

4172 °F (2300 °C)

Frequency:

162 kHz

Testing:

A four-urn helical coil is used for the sintering process. Power is applied for thirty minutes under a nitrogen flooding atmosphere and temperature is held at 4172 °F (2300 °C). The tungsten successfully sinters, the tantalum does not.

Benefits:

-

More consistent structure

-

Create high heat intensity very quickly

-

Energy efficient & environmentally friendly

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000