Note: Wire stripping (varnish removal)

Objective:

Heat wires to burn off the varnish coating

End Product:

Copper wire bundle

Equipment:

Ambrell 7.5 kW induction heating system equipped with a remote heat station, containing one 1.00 μF capacitor.

An induction heating coil designed and developed specifically for this application.

Materials:

Flat copper wire bundle of wires with a rectangular cross-section of .025 in2 (.0635 cm2)

Temperature:

1300 °F (704 °C)

Frequency:

204 kHz

Testing:

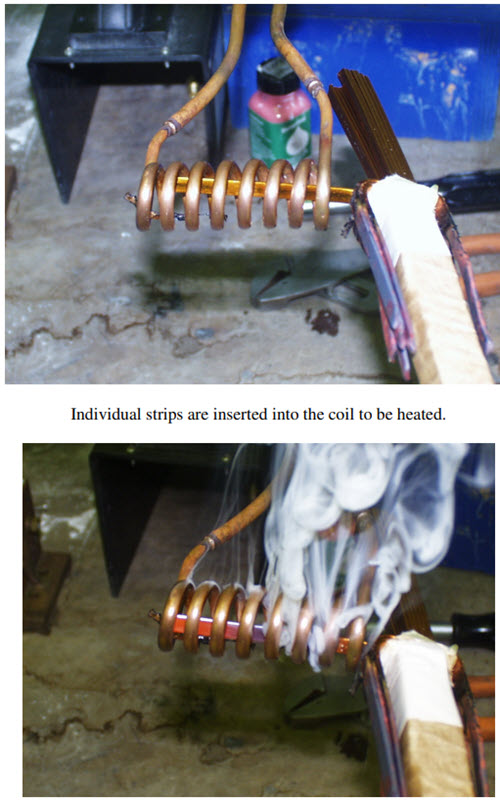

An eight-turn helical coil is used to generate the desired heat pattern. The coil has a 0.62 in ID. An individual wire is inserted and heated to burn off the varnish for 5 seconds. Larger cross sectional areas require a longer heat time or higher power. After the heat cycle, each wire is removed from the coil and allowed to cool at a natural rate.

Benefits:

Compared to mechanical scraping, induction heating is faster and highly repeatable for consistent results

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000