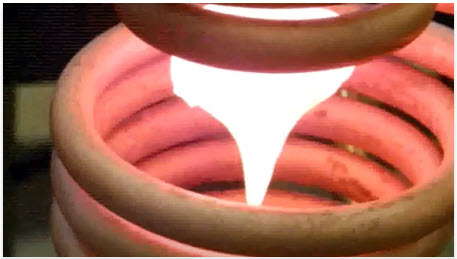

Levitation Melting

How does levitation melting with induction work?

Levitation melting with induction produces small quantities of electrically conductive material, suspending and melting the material with force enough in the coil to counter gravity.

Our Systems for with Induction

Headline

Add your content here.

Headline

Add your content here.

Headline

Add your content here.

Headline

Add your content here.

Four Ways To Contact Ambrell for Support

AMBRELL CORPORATION

1655 Lyell Avenue

Rochester, NY 14606

United States

![]() Directions

Directions

T: +1 585 889 9000

F: +1 585 889 4030

Contact Sales

Contact Orders

Contact Service

AMBRELL B.V.

Holtersweg 1

7556 BS Hengelo

The Netherlands

![]() Directions

Directions

T: +31 880 150 100

F: +31 546 788 154

Contact Sales

Contact Orders

Contact Service

AMBRELL Ltd.

Front Suite, 1st Floor, Charles House

148-149 Gt Charles Street

Birmingham, B3 3HT

United Kingdom

T: +44 1242 514042

F: +31 546 788 154

Contact Sales

Contact Orders

Contact Service