Note: Curing Adhesive on Steel Motor Shaft for Bonding

Objective:

Cure adhesives on the internal wall of a steel motor shaft to bond electronic stress/strain gauges into place.

End Product:

Motor shaft

Equipment:

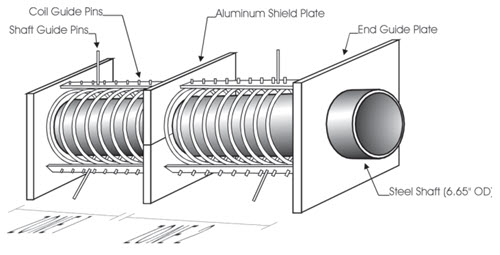

- Ambrell 1kW induction heating system equipped with a remote workhead enclosure for double capacitor/buss modules. Zone 1 needs a 0.25 μF capacitor, while Zone 2 requires 0.66 μF

- An induction heating coil designed and developed specifically for this application.

Materials:

Steel shaft measuring 6.65 in (168.9mm) OD, 5.5 in (139.7mm) ID and 70 in (1.8m) long. Aluminum shield plate and two end guide plates.

Temperature:

285 °F (140.6 °C) > 300 °F(148.9 °C)

Frequency:

160 kHz

Testing:

A complex two coil system, shield and stud systems used to provide proper axial alignments of the shaft & coil while allowing the fixture to be open for removal of the shaft. The aluminum shield separates the two required heat zones. An average temperature of 290 °F(143.3 °C) is maintained for 1.5 hours.

Benefits:

-

Precise, accurate control of heat placement

-

Minimized coating defects

-

Repeatable results

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000