Note: Shrink fit a carbon graphite ring insert into an outer steel band

Objective:

To heat a steel band to 1000 °F (538 °C) and insert a carbon graphite ring into the center of the steel band.

End Product:

graphite ring

Equipment:

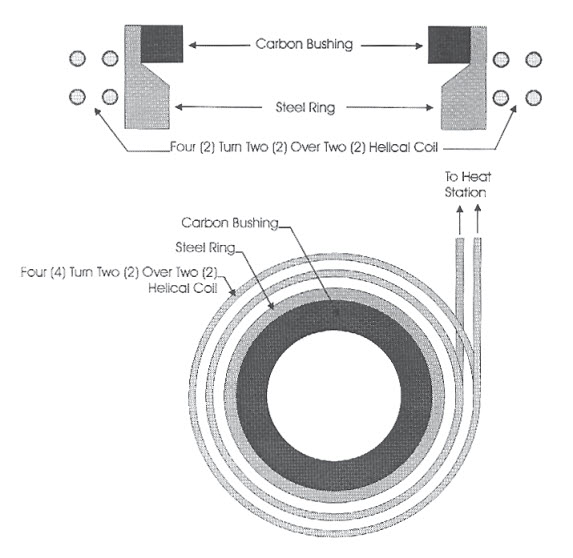

Ambrell EKOHEAT 10 kW, 50-150 kHz solid state induction power supply with a workhead and coil specifically designed for this application.

Materials:

4340 steel ring 8 in (20.3cm) OD x 7.75 in (19.7cm) ID, .895 in (22.7mm) thick, carbon graphite ring insert

Temperature:

1000 °F (538 °C)

Frequency:

132 kHz

Testing:

A four turn, two-over-two helical coil was used for heating the steel ring. Power was applied for 14 seconds to reach the target temperature of 1000 °F (538 °C), the carbon graphite ring was then inserted and the assembly was allowed to cool which created a strong joint between the two pieces.

Benefits:

-

Accurate and repeatable results

-

Reduced cycle time, lower consumable expenses

-

Even distribution of heating

-

Ease of integration into existing production lines

-

Energy efficient

-

Hands-free heating that involves no operator skill for manufacturing

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000