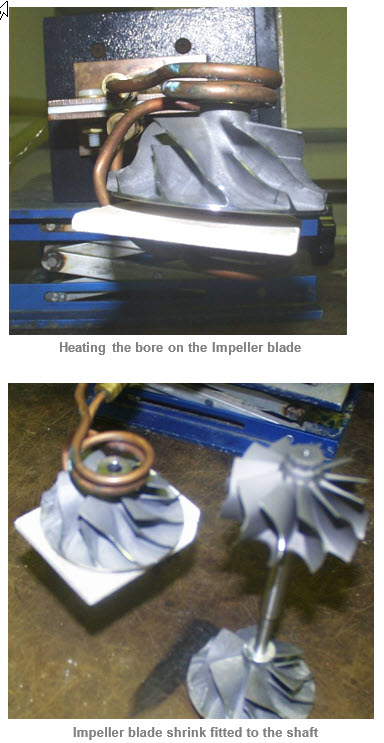

Note: Shrink-fitting auto turbo charger impeller blades onto an aluminum shaft

Objective:

To heat aluminum impeller blades to 200 °F (93 °C) and shrink fit them onto shafts.

End Product:

turbo charger

Equipment:

Ambrell EASYHEATTM 3.5 kW, 150-400 kHz solid state induction power supply with a workhead and coil specifically designed for this application.

Materials:

Aluminum impeller blades with a .28 in (7.109 mm) bore, aluminum shaft

Temperature:

200 °F (93 °C)

Frequency:

255 kHz

Testing:

A split two-turn helical coil is used to evenly heat the opening on the impeller blade. The impeller blade is heated for 20 seconds to reach the target temperature of 200 °F (93 °C). The impeller blades are then removed from the coil and slipped over the shaft to complete the shrink fitting application.

Benefits:

Accurate and repeatable results

Reduced cycle time, lower consumable expenses

Even distribution of heating

Ease of integration into existing production lines

Energy efficient

Hands-free heating that involves no operator skill for manufacturing

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000