Induction Cap Sealing

- Home

- How It's Used

- Cap Sealing

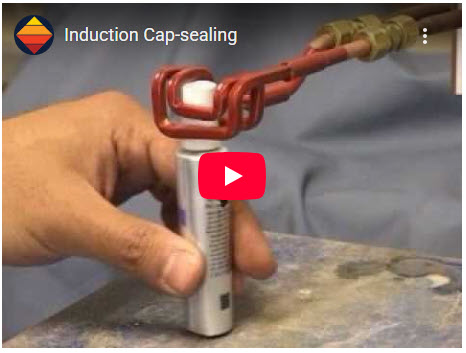

What is Induction Cap Sealing?

The electromagnetic field generated by the induction sealing system heats the foil/polymer liner placed over the container opening as it passes under the induction coil. This heating melts the polymer, sealing the liner upon cooling.

Induction generates an electromagnetic field in a work coil that induces currents in the conductive material of a workpiece placed within or near the coil. Friction from these currents elevates the temperature of the workpieces and filler to be brazed.

Benefits of cap sealing with induction

-

Meets tight production tolerances with precise localized heat to small areas creating pinpoint accuracy

-

Increases production rates with faster heating cycles

-

Reduces defect rates with repeatable, reliable heat

-

Eliminates variability from operator-to-operator, shift-to-shift

-

Maintains metallurgical characteristics of the individual metals

cap sealing Application Notes

Select from our collection of cap sealing notes, developed over 40 years supporting our customers. Read how we helped to solve their process heating challenges!

Sealing an Aluminum Cap Seal on a Plastic Jug

Sealing an Aluminum Cap Seal on a Plastic Jug

To heat one aluminum cap seal on a plastic jug for a cap sealing application. The client is replacing past systems that no longer work for their process.

Bonding Foil to a Plastic Bottle

Bonding Foil to a Plastic Bottle

It was confirmed that the aluminum heated sufficiently to create a bond between the foil and the bottle, meeting the client's objective.

Sealing Aluminum Caps (Beverages)

Sealing Aluminum Caps (Beverages)

Induction delivers the same result time after time, making it ideal for this high-volume manufacturing process. The space-efficient 45 kW EKOHEAT fits nicely into the client's floor plan.

An EASYHEAT and a workhead required a minimal footprint, saving the client floor space.

Sealing an aluminum disk onto a plastic cap

Sealing an aluminum disk onto a plastic cap

Induction heating enabled the aluminum to seal to the plastic cap quickly without the cap being damaged. The customer desired a quick rate which would make in-sourcing the process worthwhile, and induction heating exceeded the targeted production rate thanks to its fast heating.

Heating pre-assembled plastic tube and cap

Heating pre-assembled plastic tube and cap

Customer currently has Ambrell equipment and would like to increase their run rate.

Sealing aluminum foil cap to plastic bottle

Sealing aluminum foil cap to plastic bottle

Coil design can be incorporated to fit a wide range of production setups. Hands-free heating, involves no operator skill for manufacturing and directly heats only perimeter of foil.

Cap Sealing 3.5 Lotion Container

Cap Sealing 3.5 Lotion Container

Power is applied directly to the foil; no energy is wasted heating the cap or the surrounding air or parts.

Cap Sealing; Shampoo Container

Cap Sealing; Shampoo Container

A three-turn two-position helical coil is used to heat the aluminum foil in a tunnel style assembly. Product (containers) passes easily under the induction coil.

What are the Benefits of Cap Sealing with Induction Heating?

Precise bonding due to the efficient delivery of energy provides a high quality seal. It is repeatable and reduces the likelihood of product quality issues

How Can Cap Sealing with Induction Improve Production Speeds?

Induction heating systems are able to be integrated into production lines with a high throughput rate. The efficiency and consistency of induction heating will lead to significant improvements in production speeds and reliability of the joint created.

How Can Induction Cap Sealing Reduce Downtime?

Due to the reliability and repeatability of induction heating systems the downtime from production line stoppage is reduced as the joints created are done in a controlled matter reducing the likelihood of making bad product requiring rework or production line setup changes.

Popular Cap Sealing Note

Popular Cap Sealing Video

From our blog

More cap sealing resources

Our Systems for cap sealing with Induction

Headline

Add your content here.

Headline

Add your content here.

Headline

Add your content here.

Headline

Add your content here.

AMBRELL CORPORATION

1655 Lyell Avenue

Rochester, NY 14606

United States

![]() Directions

Directions

T: +1 585 889 9000

F: +1 585 889 4030

Contact Sales

Contact Orders

Contact Service

AMBRELL B.V.

Holtersweg 1

7556 BS Hengelo

The Netherlands

![]() Directions

Directions

T: +31 880 150 100

F: +31 546 788 154

Contact Sales

Contact Orders

Contact Service

AMBRELL Ltd.

Front Suite, 1st Floor, Charles House

148-149 Gt Charles Street

Birmingham, B3 3HT

United Kingdom

T: +44 1242 514042

F: +31 546 788 154

Contact Sales

Contact Orders

Contact Service

Sealing a Plastic Container

Sealing a Plastic Container