Note: Heating a Flanged Part Before Welding

Objective:

To heat a Nickel-flanged part (a mold) for a preheat before welding application.

End Product:

Nickel part

Equipment:

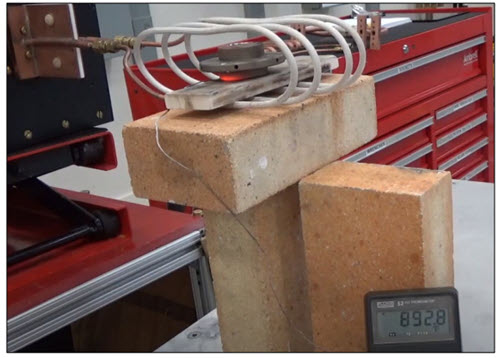

Ambrell EKOHEAT 15 kW, 50-150 kHz induction heating power supply with a workhead and coil specifically designed for this application.

Materials:

Two different Nickel parts

Temperature:

900 °F (482 °C)

Frequency:

84 kHz

Testing:

A custom-designed single-position multiple-turn oval coil was built to generate the required heating for the preheating application. Initially, a helical coil design was used which did heat the part faster, but the pattern wasn't uniform. With the oval coil and an EKOHEAT 15 kW induction heating system, the heating time was 45 seconds and a uniform heating pattern was evident. The speed and heating pattern met the client's objectives.

Benefits:

-

Speed: Induction met the client's time objective for this preheating application.

-

Repeatability: The client can expect the same result in the same amount of time every single time, which is ideal for their manufacturing process.

-

Conducive to Manufacturing Processes: The client had been using an offline oven, but preferred the heating occur in a cell, which is an application induction heating is commonly used for.

-

Size of System/Workhead: With induction the workhead can be placed away from the system itself, making it a great fit for a work cell.

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000