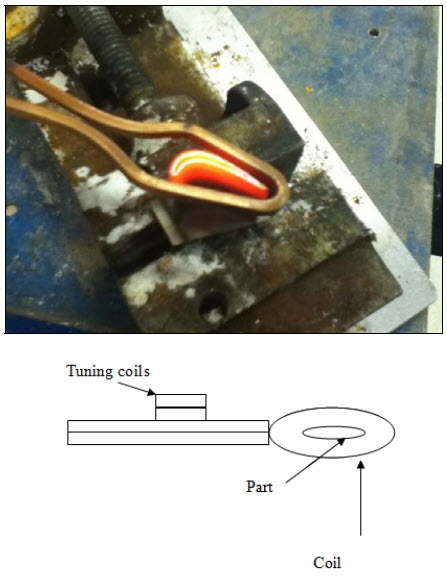

Note: Preheating a turbine blade (welding)

Objective:

Heating a turbine blade to 1850 °F (1010 °C) for a welding application

End Product:

Turbine blade

Equipment:

Ambrell EASYHEAT 5060 LI, 4kW 150-400 kHz induction heating system equipped with a remote heat station containing two 1.5 μF capacitors

A single-position one-turn induction heating coil designed and developed specifically for this application

Materials:

Steel turbine blade

Temperature:

1850 °F (1010 °C)

Frequency:

305 kHz

Testing:

The single-position one-turn induction heating coil was designed to heat the tip of the turbine blade. With a 6kW EASYHEAT power supply, the turbine blade was heated to temperature within the targeted time of one minute.

Benefits:

-

Speed: The client wanted the part heated to temperature within one minute, which the process achieved

-

Precision: The client desired uniform heating across the tip of the blade, which was attained with the proposed process

-

Part quality: The end result is a preheating process that allows the part to move quickly to the welding step while meeting all quality requirements

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000